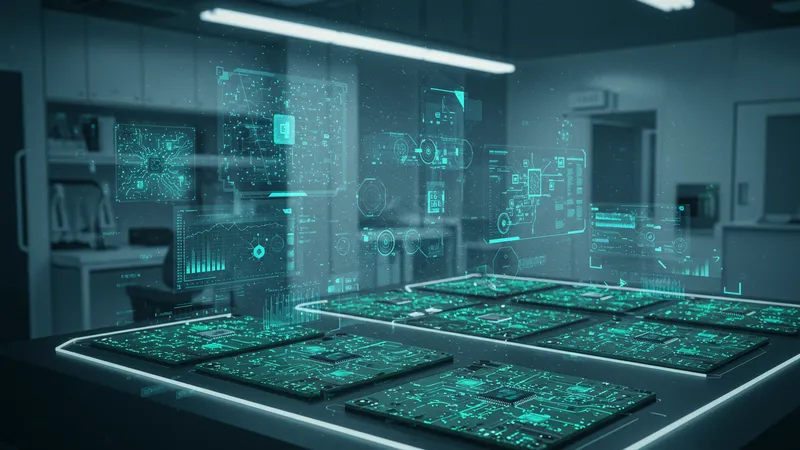

Unbeknownst to most, the world of medical devices is undergoing a quiet revolution led by innovative PCB design solutions. What if we told you that these seemingly simple circuit boards are transforming patient care as we know it?

With the rapidly aging population and the push for more personalized healthcare, the stakes have never been higher. The demand for precise, reliable medical devices is skyrocketing, and cutting-edge PCB designs are at the heart of this technological evolution.

PCBs in medical devices aren't merely about connecting circuits; they're revolutionizing patient diagnostics with unprecedented accuracy. Imagine a pacemaker whose PCB design can adjust to the body's needs dynamically. Now picture that power placed in even smaller, wearable devices that can predict health issues before symptoms appear. But that’s not even the wildest part…

An overlooked aspect of PCBs in medical innovation is their ability to drastically reduce healthcare costs. They allow for the development of cheaper, more efficient devices, making advanced healthcare technology accessible to more people worldwide. There's more here than meets the eye—a transformation that promises to redefine the healthcare industry. What happens next shocked even the experts…

Miniaturization of PCBs is not just a technological goal; it is a critical need in the medical field. With devices needing to be less intrusive and more portable, the size of the PCB is paramount. Smaller PCBs can be embedded in minimally invasive medical tools, allow for easier patient wearability, and can support the integration of more complex functionalities. The healthcare implications are wide-reaching, potentially changing the way we monitor patient health daily. But there’s one more twist…

In the realm of diagnostics, miniaturized PCBs enable the creation of advanced, handheld diagnostic tools, empowering healthcare providers to deliver immediate insights. This is particularly transformative in remote or under-resourced areas where access to large medical equipment is limited. Advanced diagnostic capabilities without the need for sprawling infrastructure? That certainly changes the game. What you read next might change how you see this forever.

However, miniaturization does not come without challenges. Engineers face hurdles like heat dissipation and maintaining performance standards. Overcoming these barriers requires top-notch design tools and a thorough understanding of the materials involved in PCB production. Yet, with every obstacle comes an opportunity for enhanced innovation and creative breakthroughs. And this is just scratching the surface…

Among the innovators in this arena, companies are fiercely competing to push the boundaries of what's possible. As result, patents are filed, new prototypes emerge, and the dream of universal medical care through technological ingenuity becomes less of a dream and more of a reality. But don’t go anywhere just yet; the next revelation could transform your expectations entirely.

One might not suspect it, but materials used in PCB production play a pivotal role in the performance and reliability of medical devices. From flexible substrates that enable contouring to the patient's body to high-thermal-conductivity materials that improve heat dissipation, choosing the right materials can dramatically advance device capabilities. What if the very materials we often overlook are the heart of medical marvels? But hold on, there’s an intriguing layer yet to uncover…

Durability remains a key factor, especially for implantable devices, where longevity is critical to patient health. Selecting materials that can withstand biological environments without degrading ensures these devices remain effective over longer periods. Imagine a heart monitor that remains accurate and functional without replacement for several years – it's more than a cost-saving; it’s a lifesaver. Ready for another twist?

Innovations in eco-friendly materials are shifting the landscape of PCBs in medical devices as well. With environmental impact under scrutiny, manufacturers are exploring biodegradable and less harmful substances, ensuring that while healthcare advances, the planet doesn't pay the price. These innovations also address regulatory and compliance challenges, pushing boundaries further. But this is just the beginning of a sustainable evolution…

And yet, it's not only about what the materials can do for patients today; it's about the potential they represent for tomorrow. Every leap in material science opens doors to new possibilities, making even the most ambitious medical device designs feasible. What happens when PCB materials become as adaptable as the devices they empower? Stick around; the most surprising revelations are still ahead.

As the intricacies of PCB design in medical technology develop, so do the associated costs. While initial investments in cutting-edge PCB technologies and sophisticated software may seem daunting, the benefits they yield far outweigh these expenditures in the long run. The question is, why aren't we discussing this more openly? But there's more to this cost story than meets the eye…

Hidden costs often come from the need for extensive testing and validation in medical contexts, demanding resources that ensure each device meets stringent safety standards. This rigor is non-negotiable, as lives depend on the precision and reliability of these devices. A single oversight could lead to catastrophic failures—a reality at odds with the desire for fast iteration and deployment. Here’s where it gets really interesting…

Cost management isn't only about managing expenses but about maximizing returns through enhanced performance and reduced long-term expenditure. Businesses are finding innovative ways to balance these scales, including partnerships with tech firms and academia to fund research jointly, exploring cost-effective alternatives, while maintaining sophisticated device functionality. Isn’t it time we rethink our approach to healthcare investment strategies?

Despite these challenges, many in the industry see the high initial costs as vital investments in the future of healthcare. Why? Because the successful integration of PCB technology in medical devices offers unprecedented possibilities for saving lives and improving health outcomes globally. But wait, there’s still more that hasn’t been accounted for – you’ll want to continue exploring this narrative…

Complexity in PCB design is not uncommon; in fact, it's becoming a norm within the medical technology sphere. With the need for more features and functionalities packed into smaller devices, design intricacies have risen dramatically. But it’s not always complexity for complexity’s sake; it’s a balancing act of sophistication and practicality. And here lies a hurdle few anticipate…

Innovation demands complexity. Advanced multi-layer PCBs and intricate circuit layouts are necessary to support the growing demands for device performance and connectivity. This complexity, however, requires robust tools and skilled professionals, at times making it harder for smaller companies to compete. This could potentially slow down innovation, or does it present a new opportunity to simplify? Dive deeper with us to learn more…

There's a persuasive argument that complexity also brings resilience. Devices must function flawlessly in unpredictable environments, and feature redundancy within complex designs ensures that even if one section fails, the device continues to operate. This resilience strengthens trust across the medical industry that these devices work under pressure. But it’s also a call for simplification, a fine balance yet to be struck. Are we ready to embrace this harmonious approach?

Moving forward, collaboration becomes key. Listed are cross-industry collaborations with tech giants, bringing diverse expertise to solve unprecedented challenges of PCB complexity. By merging perspectives, the medical tech world becomes less about competition and more about shared advancement, ensuring devices aren’t just complicated, but comfortably complex and consistently impressive. What comes next could be the key to a breakthrough in synergy and innovation…

The advent of sophisticated computer-aided design (CAD) software has profoundly altered the landscape of PCB design for medical devices. These tools have zipped past the days of manual design, ushering in an era where precision engineering meets creativity in unprecedented ways. Can you imagine the possibilities when computers do the heavy lifting, freeing up innovators to dream bigger than ever before?

CAD software allows designers to prototype and tweak designs at breakneck speeds, reducing both time and labor costs while increasing accuracy. These dynamic modifications and simulated environments let developers catch issues before a physical prototype is ever made. Imagine trimming weeks or even months off development timelines! But there’s another layer to this transformation waiting to be peeled back…

Another benefit of CAD tools in PCB design is enhanced collaboration. With cloud-based platforms, teams across the globe can work seamlessly together, removing traditional geographical barriers. This not only fosters faster iterations but pools minds from different disciplines to solve multifaceted issues in unique, innovative ways. It’s like having a think tank on-demand and shrinks the world into a cornerless innovation hub. What’s the next frontier for PCB design and CAD collaboration?

However, there's a caveat: not all CAD softwares are created equal. Understanding and selecting the most suited option for specific medical device needs can be complex yet crucial. As design tools continue to evolve, unlocking their full potential requires expertise and continuous adaptation. The synergy between the right tools and talented minds beckons a new era of medical device advancement—an era that promises to take healthcare to stratospheric heights.

Outsourcing PCB design might stir mixed opinions, but it's proving indispensable in the rapid advancement of medical technology. Handing over design tasks to specialized firms allows companies to focus on core healthcare challenges rather than the nitty-gritty of circuit design. But there lies a hidden advantage, not just cost savings, at the helm of this shift…

Finding an expert in PCB design who understands the medical sphere can dramatically cut down on project timelines and elevate the quality of the end-product. These experts bring with them a breadth of experience and the kind of insights that can’t be easily replicated in-house. The results? Higher fidelity in the final product and often, a surprise boost in innovation. But is outsourcing fearfully underutilized, or is there more beneath this layer?

Some argue that outsourcing may lead to consistency concerns or a loss of intimate control over the project, potentially impacting quality or unique branding. However, when managed properly, relationships with external design teams can be highly mutually beneficial and lead to unforeseen highs in productivity. The key lies in effective communication and managing expectations. Ready for a real eye-opener on strategic collaborative leadership?

On the flip side, outsourcing can provide a fresh perspective that in-house teams might lack. Designers from different sectors bring new insights that can lead to unexpected, innovative solutions. Thus, outsourcing opens the doors to worldwide expertise, making it far more than just a cost-saving measure—an innovation multiplier. But within this boundary-less world, what new medical marvels might we soon witness?

IoT devices are ushering in a new era of connectivity and data aggregation in medicine, and PCBs are the silent enablers of this digital revolution. From smart inhalers sending patient data directly to doctors, to wearables tracking life-saving metrics, PCBs are critical. Are we on the verge of mass-adopting a healthcare system that's always online?

This integration means more real-time data facilitates faster and more accurate healthcare decisions. With the right PCB design, IoT medical devices become more reliable, further enhancing patient care. But integrating IoT into medical requires not just precision in device creation, but securing data, which is a feat on its own. So is improved care worth the increased security dilemma? Possibly more than imagined…

Challenges abound, particularly in terms of security vulnerabilities. But as global standards improve, and security becomes as integral as the device functions themselves, confidence grows. Engineers are now as focused on PCBs enabling encryption and secure data transfer as they are on the functional aspects of the devices. Could this be the crucial junction between healthcare and tech safety?

With the potential for widespread deployment of IoT in medicine, concepts once deemed science fiction could become a part of everyday healthcare. Preparing for wellness appointments in reality through PCB-enabled smart devices suggests a future where healthcare is more predictive rather than reactive. Keep your imagination open because the future's horizon is brimming with possibilities yet unimagined.

In the world of medical device PCB design, no conversation is complete without addressing the often daunting arena of government regulations. Ensuring compliance while pushing technological boundaries isn’t just a recommendation; it’s a necessity. But are these regulations a burden, or the catalyst for innovation that the industry desperately needs?

Regulations exist to protect patients, ensuring devices meet rigid safety and efficacy standards. This pressure can drive designers to greater heights of precision and creativity, contributing to safer, more effective medical solutions. But the process is never straightforward. Is this constant push and pull stifling ingenuity, or does it hone it to form more resilient innovators? Here’s another perspective to ponder…

On the flip side, regulatory bodies can sometimes lag behind when it comes to understanding rapidly developing technologies. Manufacturers find themselves waiting as new criteria crawl through legislative processes, delaying time-to-market. The question is whether a better synergetic model can be developed, one where policy evolves concurrently with science and tech advancements. Now, that might be a game-changer.

But rather than seeing this dynamic as roadblocks, forward-thinking firms view regulation as a driver of international excellence and trust. Breaking the next regulatory hurdle could provide just the edge needed for a product to soar in global markets. Conquering compliance isn't just about meeting standards; it's about setting them. Could success mean rewriting the book on global innovation in health technology?

The PCB industry, much like the medical devices it supports, is full of potential for the future. Trends such as AI-driven PCB design, modular components, and biocompatible-PCBs stand poised to spark a dramatic evolution in medical technologies. Could these developments represent the new frontier for health tech, just waiting to be explored?

AI is already transforming healthcare through diagnostics, treatment, and patient care. When applied to PCB design, AI offers unparalleled insights and efficiencies, highlighting design improvements and error predictions that boost both quality and speed. This seamless integration of technology is more than just a little promising—it’s a paradigm shift for the industry.

In the realm of modular PCBs, customizability becomes king, allowing designers to tailor each component of the device specifically to individual needs. This flexibility can significantly reduce waste, heightening sustainability while still maintaining device precision and reliability. But this innovation poses a question: Could universality in medicine be closer than ever imagined?

Biocompatible PCBs represent another leap forward, eliminating issues associated with implantation and long-term presence inside the body. As these new materials and approaches gain traction, the boundary between device and patient blurs, creating seamless integrations. It's a dazzling future landscape, inviting you to picture a world where technology is not just an assistant, but a part of our very being.

Environmental considerations have never been more pertinent in the medical tech sphere, with sustainability becoming an increasingly pivotal aspect of PCB production. With companies globally under pressure to reduce their carbon footprint, the drive for eco-efficiency in medical devices is more than a market trend—it’s a necessity for our planet's survival.

Traditional PCB manufacturing involves hazardous substances and environmentally detrimental waste. However, evolving technologies are enabling the reduction of harmful chemicals and promoting the use of recycled materials, creating not only safer work environments but also massive sustainability improvements across the board. But there’s more to uncover in this green evolution…

The push for eco-friendly PCBs is likely to foster industry-wide changes that impact on how devices are designed and disposed of. Adding life-cycle analysis to manufacturing processes ensures that every aspect, from creation to disposal, is as environmentally friendly as possible. Yet there's potential for environmental considerations to spur innovation, despite the seeming constraints they impose.

While challenging, these sustainable initiatives can ensure that the future of medical technology is ethically responsible and environmentally sustainable, securing not only lives but the future of the planet. Taking on this challenge is an opportunity for companies, governments, and consumers to forge partnerships that redefine standards. What steps will guide us toward a responsible med-tech ecosystem moving forward?

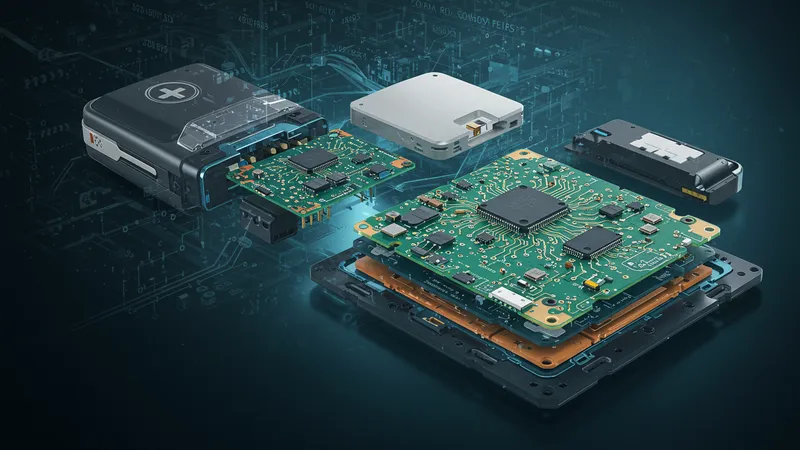

The integration of hybrid systems within PCB design for medical devices is proving revolutionary. By blending traditional circuit systems with cutting-edge technological advances, hybrid solutions offer performances previously thought unattainable. But what exactly lies at the heart of this hybrid revolution?

These systems provide advantages such as increased functionality, enhanced energy efficiency, and reduced size. As technology evolves, understanding how to seamlessly blend these roles not only poses interesting design challenges but yields remarkable performance benefits. The question remains, who is leading the charge in blending these distinct systems?

Moreover, hybrid system integration within PCBs allows for the convergence of several medical modalities into a single device. Imagine a device that simultaneously monitors heart health while assessing glucose levels—essentially combining multiple diagnostic functions into one! But there’s more on how hybrid systems could redefine healthcare's possibilities in unprecedented ways.

The implications extend far beyond individual devices, potentially transforming entire ecosystems of care by integrating platforms that communicate and function in harmony with one another. Navigating this complexity requires novel collaboration and research, uniting eminent thinkers across multiple disciplines to co-create unfathomably rich and interconnected solutions for medical care. Can we envision a world of unfathomable progress yet?

Throughout the rapid evolution of PCB design in medical technology, case studies have showcased breathtaking success stories. These real-world applications demonstrate the impact of innovation and provide roadmaps for future advancements in the sector. Are we ready to glean lessons from these triumphs to forge our future pathways?

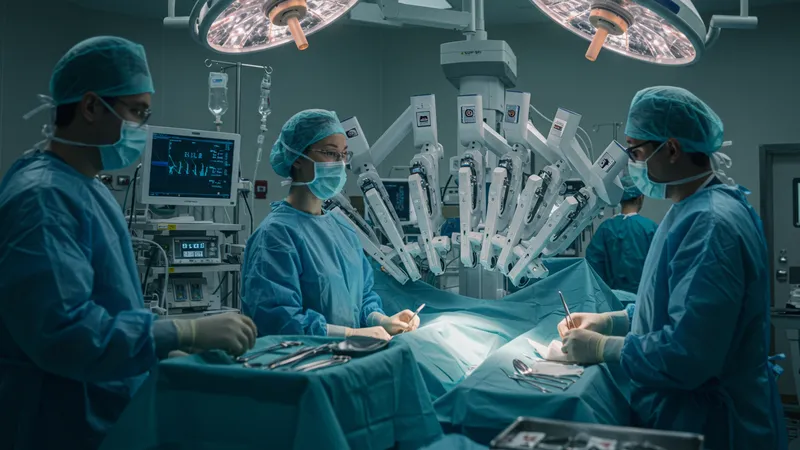

Consider the use of PCBs in precision surgical robots, which allow for minimally invasive procedures with enhanced accuracy. Through detailed annotation and learning from these cases, medical personnel can engage in surgeries with razor-sharp precision, lessening patient recovery times and improving outcomes. Imagine the lives transformed through these technological revolutions!

Another success story lies in wearable health monitors that have now become commonplace due to advanced PCB designs. These devices provide continuous monitoring and often early warning signs for various health conditions. As the technology has become more accessible, it reflects a democratization of healthcare, taking critical monitoring tools into the home.

These case studies not only inspire but serve as blueprints for cutting-edge technology. By looking into these successes, stakeholders can better anticipate challenges and innovate proactively. They reinforce that, in the landscape of PCB-enabled medical technological advancement, the sky truly is the limit.

In the kaleidoscope of medical technology, PCB design stands as an unsung hero, quietly catalyzing miracles daily. The challenges are real, yet the rewards are boundless. Through every hurdle, the industry grows more resilient, innovative, and interconnected than ever before. By embracing technology with a conscious curiosity and respect for sustainability, we maintain a commitment not only to technological benefit but also to humanity itself.

As we stand on the brink of tomorrow's healthcare advancements, each reader has a role to play. Share this article, bookmark it, and together, let's champion a conversation that pushes boundaries and ignites the next epoch of medical marvels. Because technological evolution is not just inevitable—it's the story we get to pen together.