Did you know hydraulic systems are revolutionizing industries with groundbreaking pressure-compensated control solutions? Companies are harnessing these systems to boost efficiency like never before.

In an era where precision is paramount, understanding hydraulic pressure compensation could be your gateway to unprecedented control and energy savings. But that's just scratching the surface...

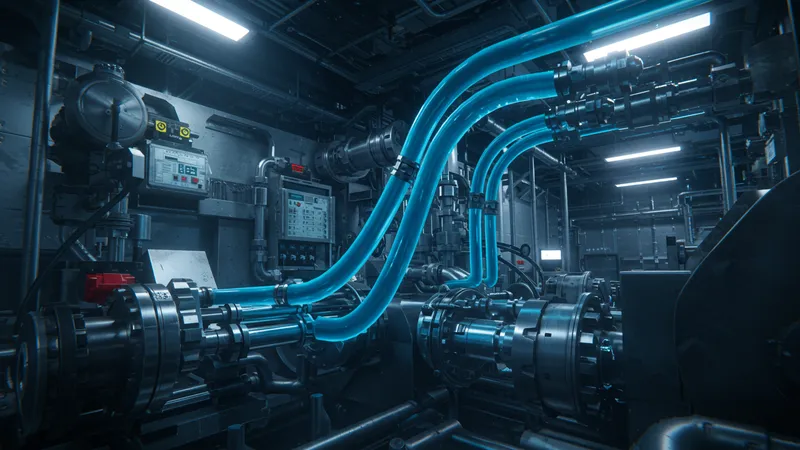

Imagine hydraulic systems fine-tuning themselves on the fly—constantly adjusting to deliver precise power levels regardless of changing loads. This isn't just about efficiency; it's about smarter, self-regulating machinery. But that’s not even the wildest part…

Traditional systems often waste immense amounts of energy, silently hemorrhaging costs. With pressure-compensated controls, companies are cutting expenses by up to 40%. Sounds impressive? Wait until you learn what this means for global energy conservation…

Experts were left in awe as these systems started achieving what seemed impossible. What happens next shocked even the experts, and it could transform your entire outlook on hydraulic technology...

Hydraulic systems have always been essential, but with pressure-compensated controls, they’re turning into smart entities, adjusting and optimizing autonomously. This breakthrough stems from a simple principle: balancing pressure with demand, thus eliminating inefficiencies almost entirely.

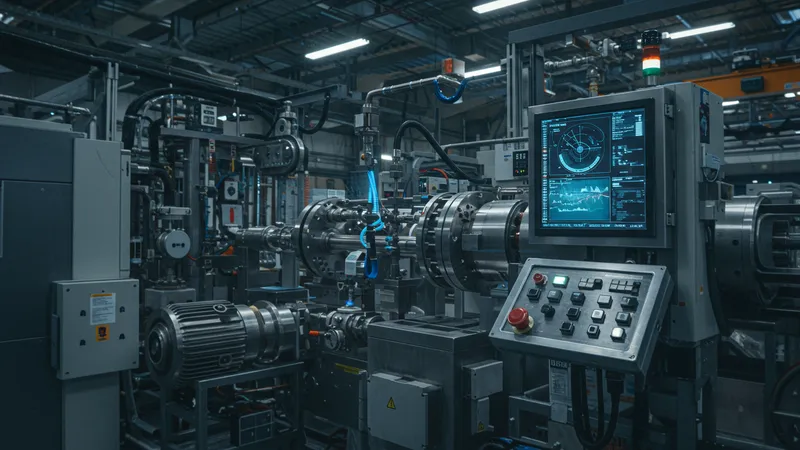

What makes this revolutionary is its adaptability. Factories using pressure-compensated systems report a dramatic decrease in maintenance needs. Imagine a world where machines predict their own repairs! But there’s one more twist—these machines can also be remotely monitored.

This remote monitoring of hydraulic systems is another game-changer. Technicians can now make adjustments from miles away, reducing downtime drastically. This level of control was a dream, now a reality shaping the fate of modern industry.

Many industries still overlook the full capabilities. The savings and efficiency gains aren’t just theoretical. Early adopters are reporting growth and cost savings that are setting new benchmarks. What you read next might change how you see this forever.

Pressure-compensated systems are leading the charge in energy conservation. While traditional machinery guzzles power, these smart systems cut consumption drastically, saving not just money but the planet in the process.

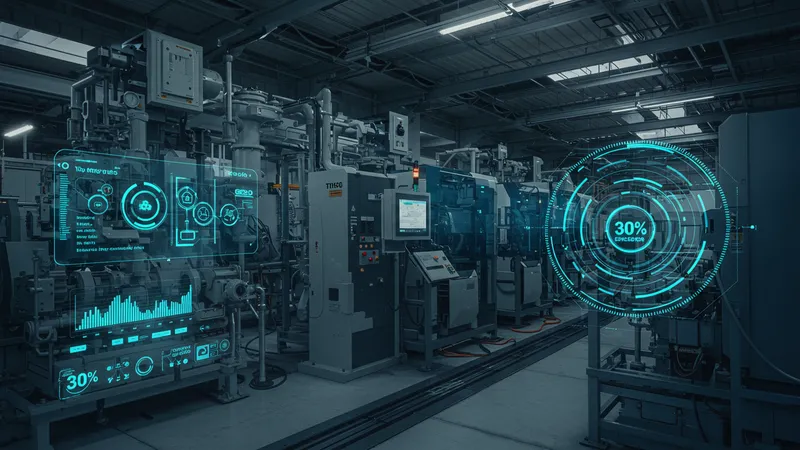

Consider this: studies have shown that factories employing these systems reduce energy costs by nearly 30%. That’s not just a reduction—it’s a revolution in industrial energy usage. But there's an insider secret: maximizing these savings requires a specific setup.

Regular maintenance and fine-tuning are key to maximizing savings. When done right, the results are nothing short of phenomenal. By creating tailored configurations, businesses can potentially exceed savings expectations, unlocking even more efficiency.

But the story doesn’t end here. There’s an innovative twist on the horizon that promises to push energy savings to an astounding new level. Stay tuned to discover this groundbreaking advancement.

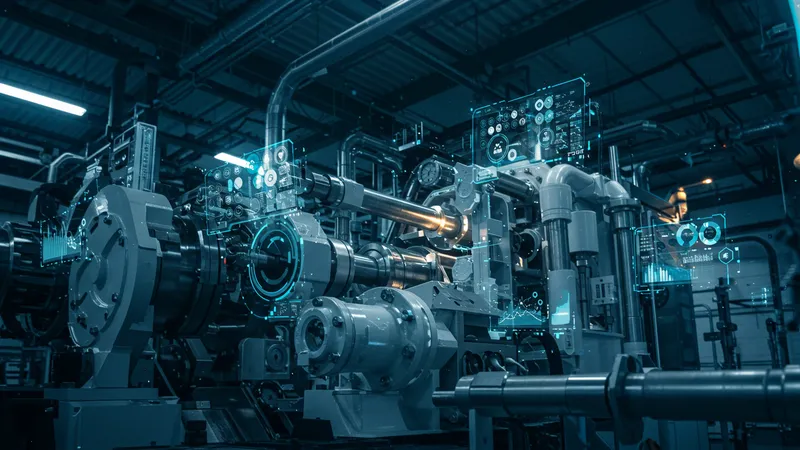

Predictive analytics is transforming how industries view maintenance, especially in hydraulic systems. Instead of routine check-ups, systems now predict and notify when they need attention, minimizing unforeseen breakdowns.

This predictive capability transforms reactive maintenance into a proactive process. Companies can plan downtime, which drastically reduces operational disruptions. But the benefits don’t stop with time management.

By anticipating maintenance needs, companies save significantly on repair costs. The financial impact is substantial, allowing for reinvestment into further innovations, creating a sustainable cycle of improvement.

Yet, there’s a deeper layer to this predictive power that most miss. A layer that intertwines with another emerging technology, pushing boundaries into uncharted territories. What you’ll learn next could redefine predictive technology as we know it.

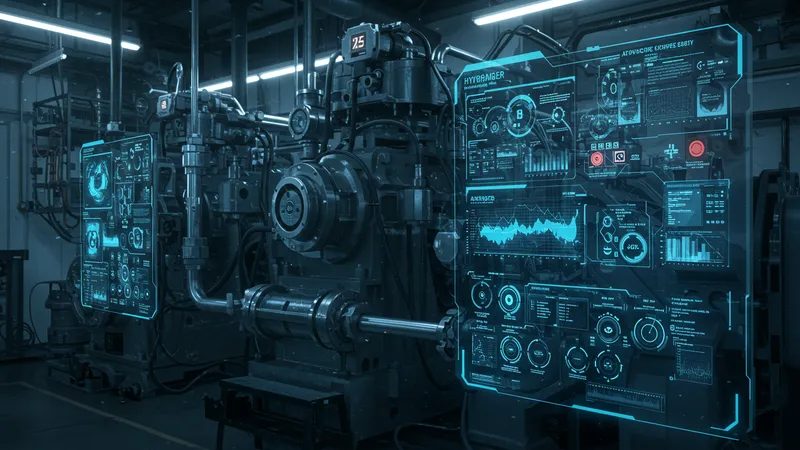

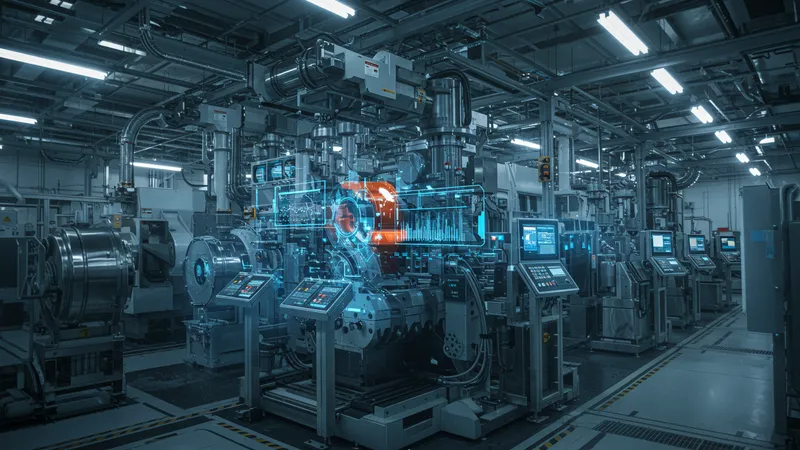

Artificial intelligence is stepping into the world of hydraulics, enhancing pressure-compensated controls with unprecedented precision. AI algorithms analyze data streams, enabling systems to make real-time adjustments for optimal performance.

This development elevates hydraulic systems into intelligent entities, integrating seamlessly with AI to predict and adapt efficiently. But why stop there? They’re evolving into even more impressive operatives.

The integration doesn’t just enhance efficiency—it enables hydraulic systems to learn. They evolve, becoming smarter with each operation, continuously refining their processes. But there’s a controversial aspect to this intelligence.

Some argue that the reliance on AI could lead to complications, blurring the lines between human control and machine autonomy. This debate is set to reshape how industries employ these technologies. The revelations on this front might just surprise you.

The shift to pressure-compensated systems isn’t just about technology; it’s a major player in economic growth. The cost savings and efficiency improvements ripple outward, impacting the broader economy.

As companies reduce overheads and boost profits, they reinvest in expansion, innovation, and workforce development. This creates a ripple effect, contributing positively to local and global economies.

Countries that embrace these advancements early see enhanced competitiveness on a global scale. They’re not just saving money—they’re leading a new industrial movement.

Yet, there’s a hidden catalyst fueling this transformation—a factor that’s often overlooked but is vital for sustaining continued growth. This element might just hold the key to future economic resilience.

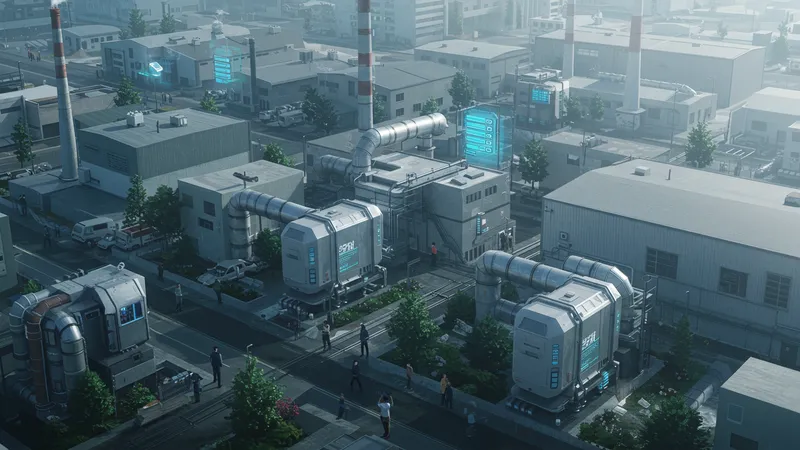

One of the most thrilling developments in hydraulic systems is the ability to control them remotely. This capability has redefined flexibility and accessibility across various industries.

Remote operations mean fewer onsite visits, which translates to reduced costs and increased productivity. Companies can manage multiple locations from a single control center, streamlining operations like never before.

However, with advancements come challenges. Cybersecurity becomes a heightened concern as these systems become more connected. Protecting this digital landscape is now a top priority.

But there’s another layer to remote capabilities—one that taps into the future of workforce management and operational efficiency. Exploring this could unveil breakthrough strategies for modern industries.

The push towards sustainability is relentless, and hydraulic systems are pivotal in this movement. Pressure-compensated controls contribute significantly to reducing environmental footprints.

By consuming less energy and optimizing resource usage, these systems are eco-friendly alternatives, aligning industrial practices with environmental goals. This is essential for long-term ecological health.

Industries leveraging these systems report not just compliance with environmental regulations but also enhanced public image and customer trust. This is crucial for modern companies striving for sustainable operations.

However, achieving true sustainability requires looking beyond immediate gains. It demands an integrated approach—a strategy that combines innovation and environmental stewardship. This blend is key to forging a path towards sustainable success.

In fiercely competitive markets, having a strategic edge is paramount. Pressure-compensated hydraulic systems provide exactly that by elevating operational efficiency to new heights.

These systems can be customized to meet specific demands, offering agility and adaptability in production. Companies harnessing this technology witness marked improvements in market position.

Customization options mean that businesses can tailor solutions to fit niche markets, carving out unique positions that competitors struggle to match.

But there’s more to this tale—a layer of strategy that few consider, which could redefine competition dynamics entirely. Unveiling this dimension could offer a blueprint for dominating industry landscapes.

Transitioning to pressure-compensated systems isn’t without hurdles. Initial implementation challenges often deter companies from capitalizing on their benefits.

The key to overcoming these barriers is comprehensive training and phased integration, which ensure smooth transitions and stakeholder buy-in.

Companies that navigate these challenges successfully set themselves up for long-term gains. They also foster a culture of innovation and adaptability.

But what about the hidden challenges that many companies overlook? Addressing these lesser-known obstacles could be critical for sustained success. Delving into these aspects reveals a roadmap for seamless adoption.

The future holds exciting prospects for hydraulic technology. Advancements are steering systems toward even greater autonomy and efficiency.

Emergent technologies promise smarter integration with IoT, enhancing connectivity and data capabilities. This synergy promises transformative impacts on operational landscapes.

Experts anticipate that as these systems evolve, they will redefine possibilities across various sectors, offering solutions previously thought unattainable.

Yet, the full potential remains untapped. Exploring emerging trends could reveal groundbreaking possibilities that might just shift the paradigm of modern engineering. What lies ahead is a compelling story that’s yet to unfold.

Hydraulic systems are now collaborating with renewable energy sources, contributing to sustainable solutions across industries.

This partnership results in dual benefits: optimizing energy use while augmenting renewable energy applications, fostering a more sustainable future.

One significant impact is the enhanced efficiency of solar and wind energy systems. The synergy facilitates energy storage and distribution like never before.

The possibilities are expansive, and collaborations are just beginning. The next phase could involve novel integrations that further blur the lines between hydraulic and renewable technologies.

Pressure-compensated systems are drivers of innovation, pushing boundaries and paving the way for new technological breakthroughs.

Industries are leveraging these systems to devise novel solutions, tackling complex challenges with renewed vigor and insight.

Such innovations lead to enhanced operational capabilities, setting higher standards for efficiency and performance across sectors.

This role is evolving, fostering collaborations among pioneers and ushering in a new era of ingenuity. What comes next could redefine the future of industry as we know it.

Pressure-compensated hydraulics offer resilience in unpredictable times, providing stability and efficiency amid challenges.

Their adaptability ensures continuous operations, even during market or environmental upheavals, cushioning industries against uncertainty.

Companies embracing these systems enjoy heightened reliability, which is crucial for maintaining competitiveness and delivering consistent outcomes.

As unpredictability persists, unlocking their full potential reveals strategies for navigating the unknown with confidence. The insights gained here can serve as a beacon for industries facing future uncertainties.

The influence of pressure-compensated hydraulic systems extends beyond direct users, impacting related industries and technologies.

Suppliers and component manufacturers benefit from increased demand, leading to innovation and growth throughout the supply chain.

This cascade effect strengthens industry relationships, creating interconnections that drive collective success and advancement.

The next steps involve leveraging these connections for greater innovation and competitiveness. Understanding these dynamics offers a strategic advantage in today’s interconnected industrial landscape.

The journey through hydraulic pressure compensation has unveiled lessons in adaptability, innovation, and strategic growth.

Embracing these systems has proven transformative, offering insights applicable across a spectrum of industries and challenges.

Looking forward, the potential is vast, with new advancements poised to further redefine possibilities, marking a new chapter in technological evolution.

This exploration underscores the importance of agility and foresight, serving as a reminder of the endless potential waiting to be discovered in the realm of hydraulic innovation.

As we unravel the layers of hydraulic advancement, it becomes clear that embracing innovation is not just an option—it’s a necessity. These technologies aren’t just transforming machines; they’re shaping the very future of industry. The true potential lies in continuous exploration and adaptation. Stay curious, engage, and be part of this dynamic evolution. Share this journey with peers or bookmark it for a deeper dive. The story, dear reader, is far from over.