Did you know that the latest advancements in grinding machines are revolutionizing modern manufacturing, setting new benchmarks in precision and efficiency? What used to take hours now happens in mere minutes, thanks to these unsung heroes of the factory floor.

In an era where speed, precision, and adaptability are crucial, grinding machines have become indispensable. They ensure perfection in a quickly evolving industrial landscape where every second counts. So, what makes these machines so pivotal right now?

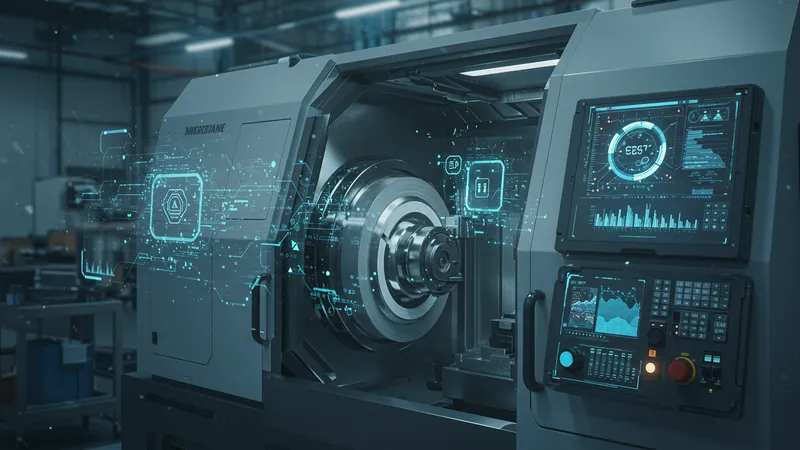

While most picture grinding machines as bulky, industrial relics, the truth is they are at the forefront of innovation. These machines are now equipped with artificial intelligence to enhance their capabilities, making them faster and smarter than ever before. In some industries, they have improved efficiency by over 50%, reducing production time and waste. But that’s not even the wildest part…

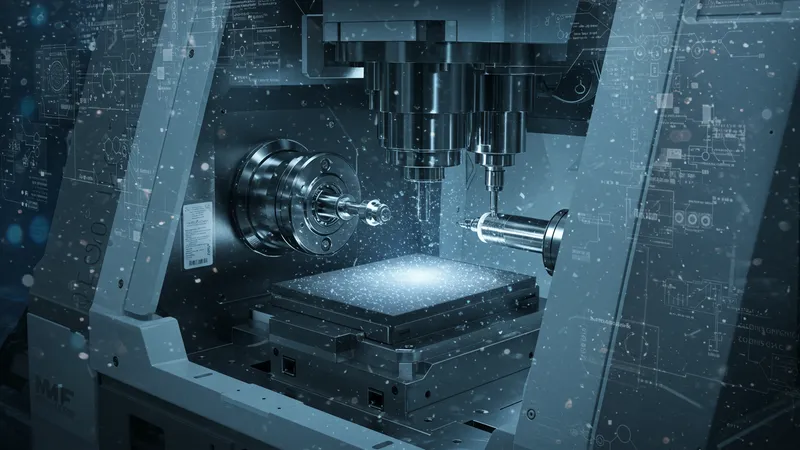

In the competitive world of manufacturing, grinding machines are quietly pushing boundaries. They have evolved from simple tool sharpeners to intricate components in medical devices and aerospace engineering. These machines, equipped with the latest tech, are redefining precision. From ultra-thin wafers in tech gadgets to custom orthopedic implants, their applications are vast. But here’s the kicker—many manufacturers are only scratching the surface of their potential. What happens next shocked even the experts…

Grinding machines are increasingly recognized for their unparalleled precision. These devices are capable of achieving tolerances within a micron, which simply is not achievable with other tools. This precision allows for the production of extremely fine features on components, which is critical in advanced industries such as aerospace and pharmaceuticals. But there’s one more twist—most companies have yet to realize the full potential of these capabilities.

For many manufacturers, tapping into the hidden capabilities of their grinding machines means rethinking their processes and embracing innovation. It’s not just about making things faster; it’s about making them better and more efficiently. This transformation isn’t always easy. It requires investment in new software, retraining staff, and sometimes even redesigning products to take full advantage of what these machines can do.

As manufacturers increasingly rely on these precise machines, a new trend has emerged: strategic partnerships with machine developers. Such collaborations ensure the continuous evolution of grinding technology, adapting to the ever-changing needs of the market. Did you know, for instance, that some of these machines now offer real-time analytics, allowing operators to optimize efficiency in real time? What you read next might change how you see this forever.

Intriguingly, some leading manufacturers have reported that by refining their machine programming and maintenance schedules, they have not only cut costs but also enhanced product quality. This positions them strategically ahead of those still operating on outdated norms. The era of grinding machines as static, predictable units is over—welcome to the age of dynamic, interactive production.

While efficiency is often touted as the primary benefit, there's more to grinding machines than meets the eye. The reduction in material waste not only improves the bottom line but also supports environmental sustainability. In many cases, the precision of modern grinding technology has led to a notable decrease in rejected components, creating less industrial waste.

Another lesser-known benefit is energy efficiency. Many contemporary grinding machines are designed to minimize energy consumption, directly reducing operational costs. Manufacturers are becoming increasingly attentive to their carbon footprints, and adapting to energy-efficient machinery is one way to tackle this issue head-on. This perspective is not just an economic savvy move; it’s an environmental imperative.

In surprising applications, these machines have a profound impact. The medical industry, for instance, utilizes grinding machines to produce customized implants with extraordinary precision—literally molding pieces meant to fit perfectly within the human body. These machines carve every detail with immaculate accuracy, ensuring better patient outcomes.

Even in traditional sectors like automotive manufacturing, grinding machines are making waves. They are instrumental in crafting highly durable components vital for vehicle safety and performance. But here’s something even more astounding: the future holds potential improvements that could revolutionize manufacturing processes fundamentally. Stay tuned as we unveil these game-changing developments.

The integration of artificial intelligence in grinding machines has been nothing short of revolutionary. With AI, machines now have the capability to learn from each task incrementally, achieving greater accuracy and efficiency with each operation. This self-improving feature is groundbreaking and represents a significant leap from traditional methods.

AI-driven grinding machines utilize advanced algorithms to monitor performance and predict potential failures, effectively reducing downtime. Preventative maintenance schedules recommended by AI can save manufacturers considerable time and resources, ensuring that machines are running at their optimal performance levels always.

A surprising element is the AI’s ability to self-correct minor deviations in real-time. This means that errors, once unavoidable, are now minimized dramatically. Imagine a world where production errors are nearly extinct—AI is making this concept a reality, fundamentally changing the manufacturing landscape.

As we delve deeper into AI's role in manufacturing, it becomes apparent that it is transforming grinding machines into smart devices that communicate across networks. This connectivity facilitates seamless integration into larger production lines, optimizing entire factories, not just individual machines. But the real breakthrough might still be around the corner… keep reading to find out how AI could further revolutionize this field.

Design innovation in grinding machines is shifting paradigms on what’s possible. No longer constrained by bulk and weight, modern machines are compact, ergonomic, and incredibly robust. New design philosophies prioritize user interaction and machine versatility, catering to a new generation of operators who value intuitive interfaces.

With the advent of high-performance materials, machine frames have become lighter, yet more durable. This improvement has allowed for greater speed and accuracy without the trade-offs traditionally associated with enhanced performance capabilities. It’s a game-changer, particularly for industries where precision is non-negotiable.

From automated operation with minimal human intervention to enhanced safety features, these design evolutions have redefined industry standards. Operators can now control machines remotely or operate multiple units concurrently, increasing overall productivity significantly. These innovations not only streamline operations but also reduce labor costs, allowing businesses to allocate resources more strategically.

As manufacturers continue to push the envelope, the next stage of design evolution is already underway. New materials and methods are being explored to further refine these machines, with the ultimate aim of achieving even higher levels of efficiency and sustainability. The future of grinding machines is bright—and it’s closer than we think.

In today's eco-conscious world, industries are more invested than ever in sustainability, and grinding machines play a crucial role in this mission. They are designed to maximize resource utilization, minimize waste, and even recycle materials when possible. This extends value chains and reduces environmental impact significantly.

One of the ways modern grinding machines achieve their sustainability goals is through energy-efficient designs and smart energy management systems. These systems monitor energy usage in real time, adjusting operations to eliminate unnecessary consumption. The outcome? Lower utility costs and a smaller carbon footprint for manufacturers.

Beyond energy savings, grinding machines have adapted to utilize water-based coolants and environmentally-friendly lubricants, eliminating the use of harmful solvents and oils. This switch is not just beneficial for the environment; it also creates a safer workplace, reducing the risk of exposure to hazardous chemicals for operators.

The effect is doubled when considering how these machines are designed for longevity. Built to withstand rigorous industrial use, they require less frequent replacement, reducing the need for new resources to manufacture. As technology continues to evolve, grinding machines are set to become even more central to achieving sustainable manufacturing practices. But there’s more to uncover—join us as we explore cutting-edge sustainability strategies up next.

In aerospace engineering, precision is paramount, and grinding machines are the unsung heroes ensuring components meet exacting standards. The ability to produce high-precision components makes these machines integral to maintaining the safety and reliability of aircraft.

A surprising application includes grinding within engine components, where tight tolerances and smooth finishes are critical. Here, the slightest deviation can impact engine performance, leading to potential safety issues. The ability of grinding machines to produce intricate designs with exacting detail is thus invaluable in this field.

Moreover, grinding machines contribute to advancements in materials science, allowing for the machining of novel materials like titanium and composites that are essential for modern aircraft. These tough materials demand precision and resilience, which only advanced grinding machines can deliver.

With aerospace industry growth steady, the reliance on these machines is likely to intensify. Upcoming innovations promise to enhance even further their contributions to aerospace engineering. To understand how these innovations are setting new standards, continue reading as we reveal the unexpected breakthroughs right around the corner.

The integration of nanotechnology in grinding machines could be the next frontier in manufacturing. This development stands to unleash possibilities for even finer precision, crafting components on a scale previously deemed impossible. Nanotechnology offers the potential for a revolutionary shift in the capabilities of these machines.

Envision grinding machines capable of manipulating materials on a nanoscale level—creating surfaces smoother and more uniform than ever before. Such capabilities could revolutionize industries like optics and electronics, where even the slightest imperfection can affect product performance significantly.

Incorporating nanotechnology doesn’t just enhance precision; it could also lead to the development of next-gen materials with extraordinary properties. As these technologies develop, grinding machines could become the key to unlocking the production of innovative new products combining strength, lightness, and super conductivity.

The research phase is already showing promise, with laboratories pioneering techniques that industry leaders are keen to develop into full-scale production. The anticipation is palpable, with potential applications spanning from miniaturized medical implants to next-gen computing components. But what other innovations might these machines unlock? The horizon is thrillingly wide open.

Hybrid grinding machines are carving a niche for themselves as versatile solutions in manufacturing, combining the strengths of various machining processes. By integrating techniques like milling, drilling, and grinding into a single machine, these hybrids offer unparalleled flexibility and efficiency.

This shift allows manufacturers to consolidate what was once a multi-step process into a single operation. The implications for speed and cost are profound, enabling quicker turnaround times and reduced labor expenses. These machines exemplify the concept of adaptability, with setups customizable for virtually any production need.

For complex products requiring diverse machining techniques, hybrid machines represent the ultimate solution. Whether crafting a multi-faceted aerospace component or a medical device with intricate geometries, these machines ensure seamless handling of challenging tasks with ease.

The potential for hybrid solutions extends beyond just efficiency. This innovation includes capabilities for handling new, lightweight composites increasingly in demand. As industries continue to evolve, the call for hybrid grinding machines is set to grow, bridging gaps between traditional machining and modern requirements. Up next, discover how far this technology can evolve.

Grinding machines have cemented their role in the global market, driving growth across myriad industries. Whether in automotive, electronics, or aerospace, their versatility means they’re vital to manufacturing processes worldwide. As globalization continues, companies seek out these machines for their unparalleled reliability and productivity.

Their presence in developing economies is especially noteworthy. As industrial sectors expand to meet global demand, the accessibility and efficiency of grinding machines solidify their place as the backbone of manufacturing infrastructure. This growth trajectory shows no signs of slowing as industrial needs and sophistication increase.

Moreover, the global market has seen a surge in demands for customized and precise manufacturing solutions, where grinding machines shine. Their ability to tailor products to exact specifications is a key factor in their market evolution. In sectors where precision is paramount, these machines offer an indispensable advantage.

Exciting opportunities await as international partnerships foster innovation and share best practices across borders. This worldwide collaboration not only leads to shared technological advancements but also to a broader adoption of the newest, most efficient grinding solutions. As industries advance, so does the global potential of grinding machines—stay tuned as we explore future landscapes!

Advancements in safety standards for grinding machine operation have transformed what was once a high-risk task into a highly automated, safe process. Modern safety protocols are designed not only to protect workers but to promote productivity by minimizing workplace accidents and downtime.

Today's machines are equipped with advanced safety features such as automatic shutoffs, sensors to monitor machine operation, and protective barriers that prevent accidental contact with dangerous moving parts. These innovations result in safer environments and incentivize more investment in grinding technology.

Training has also evolved significantly—virtual reality simulations and comprehensive training programs equip operators with the skills necessary for safe machine handling. These proactive measures empower workers to manage potential risks more effectively, ensuring human and machine interaction is as safe and productive as possible.

As manufacturers invest in these safer, smarter grinding machines, compliance with international safety standards becomes more straightforward. This not only protects employees but also enhances productivity, ultimately contributing to a more streamlined manufacturing process. The path of safety innovation is a continuous journey, and emerging technologies promise to take us even further.

The role of grinding machines in fostering innovation across industries cannot be overstated. As foundational tools in production facilities, they provide the versatility and precision needed to turn imaginative concepts into tangible products, accelerating the pace of technological progress.

These machines are the catalysts for breakthroughs in design and engineering, enabling the transformation of unconventional ideas into functional products. By allowing detailed customization and precise manufacturing, grinding machines are at the heart of shaping next-generation innovations across multiple sectors.

From debunking conventional limitations to enabling new feats in product design, grinding machines are indispensable. The tools companies rely on to create everything from the simplest part to the most complex assembly are central to maintaining competitiveness in the market.

In a rapidly evolving industrial landscape, grinding machines not only support but also drive innovation. Their role in prototyping and production marks them as crucial agents of advancement. As industries continue to explore the boundaries of what is possible, these machines will remain essential in crafting the future.

With an increasing emphasis on precision and quality, the art of grinding has been elevated to a new realm. This leap isn’t just technological but philosophical—where machinery meets craftsmanship. The result is products that are not just made, but meticulously crafted.

Grinding machines now possess the finesse needed for complex, elaborate designs that demand high levels of detail. Artisans adept in leveraging these machines’ capabilities bring products to life with exceptional craftsmanship, offering a perfect blend of technology and creativity.

The craftsmanship involved in operating these machines demands a deep understanding of both the machines and the materials being used. Skilled operators can push boundaries and set new paradigms for precision manufacturing, turning even the most intricate designs into stunning realities.

As industries place more value on bespoke, tailor-made products, the art of precision becomes a vital asset. The future calls for continuous skill evolution to keep pace with technological advancements, ensuring that craftsmanship remains at the helm of production excellence. This symbiotic relationship between man and machine continues to inspire and challenge every aspect of manufacturing.

As technology continues to shape industries, grinding machines are evolving at a breathtaking pace. As we embrace the future, manufacturers are set to benefit immensely from advancements in areas like automation, AI, and nanotechnology—all poised to further revolutionize this pivotal tool.

The potential for self-operating machines capable of learning, adapting, and optimizing via AI marks a revolutionary phase. Automation is predicted to free human operators from mundane tasks, allowing focus on innovation and problem-solving, thereby enhancing overall productivity.

Developers envision a future where grinding machines are at the fore of sustainability efforts, utilizing renewable energy sources and recycling waste materials as manufacturing paradigms shift towards eco-friendly practices globally.

As we look ahead, the scope for grinding machines is limitless. The amalgamation of science, technology, and design presents a brilliant panorama of possibilities—enabling manufacturers to keep pushing the boundaries of what can be achieved. Ready to witness how grinding machines continue to redefine the industry? The journey has just begun.

In a world driven by relentless progress, grinding machines have proven their worth time and again. They stand at the intersection of tradition and innovation, guiding industries toward new achievements one micro-millimeter at a time. Their role is pivotal and ever-expanding, not simply as tools, but as catalysts for transformation across diverse fields.

As the tale of grinding machines unfolds, consider diving deeper into their world. Share this journey, bookmark it for future insights, and remain an active participant in the narrative of manufacturing evolution. The era of the advanced grinding machine is here, and it is redefining the way we manufacture the world we live in. Where will it take us next?