Did you know that one single piece of equipment can completely revolutionize your warehouse operations? Ordinary forklifts are becoming obsolete, and companies that adapt are seeing massive gains in productivity.

In today’s fast-paced market, efficient material handling is crucial to stay ahead. Surprised how vital it is now more than ever? This evolving industry could make or break your bottom line.

Most businesses vastly underestimate the impact of outdated material handling equipment on their productivity. Studies show that modernizing these tools can increase efficiency by up to 40%. But that’s not even the wildest part...

More surprising is the fact that using AI-based handling equipment can reduce manual labor and injuries by a staggering 70%. It’s a game-changer for safety and speed. But again, that's not even the wildest part...

What happens next shocked even the experts—industries are being transformed overnight. Stay with us as we uncover essential tools and insider secrets that could entirely reshape your operational strategies.

Material handling equipment seems straightforward, but hidden costs can significantly affect your bottom line. Maintenance fees and unexpected breakdowns can skyrocket expenses. Companies often overlook these costs, focusing only on initial price—until it's too late.

What many fail to calculate is the downtime cost. Each operation standstill can translate to thousands in lost revenue. But there’s one more twist imperative to consider...

Leasing instead of purchasing equipment presents an enticing alternative. It entitles access to maintenance services, reducing unexpected costs. However, it holds a secret advantage that few realize—it can shield you from technological redundancy. What you read next might change how you see this forever.

Consider the tax benefits. Leasing can offer immediate tax deductions that buying simply does not. Often, lease payments are seen as a direct expense, enhancing cash flow. But there’s an unexpected detail in how these savings accumulate...

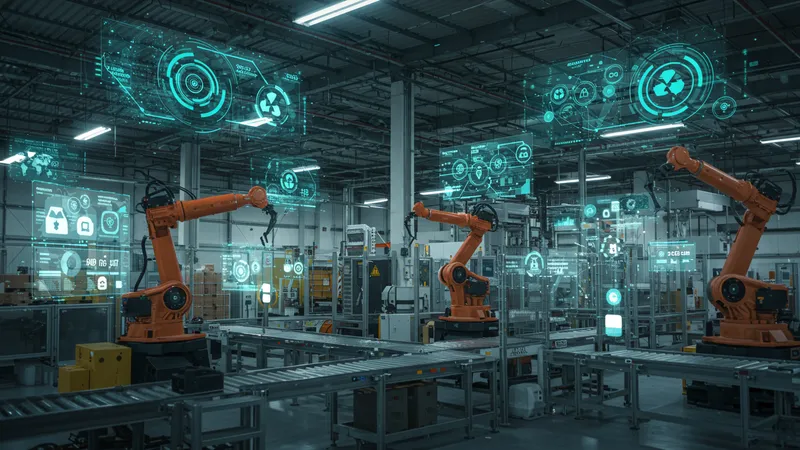

Automation in material handling is redefining efficiency in warehouses. By integrating automated conveyors and robotic systems, your operations can significantly minimize human error, reducing wastage and enhancing precision.

What's most remarkable is that these systems can work without breaks. Unlike human workers, they operate non-stop, theoretically increasing your productivity by 24%. But here's the catch you didn't see coming...

Customizable software allows these robots to adapt to your specific operational needs. While initial setup can be daunting, AI-driven optimizations lead to rapid adjustments. But there’s an insider tip that makes it even more appealing than it sounds...

The adaptability of these machines extends beyond operational tasks—they learn and optimize routes and strategies for even more efficiency. What you read next will change the way logistics are viewed within your company forever.

Innovation in material handling doesn't stop at efficiency—safety is a priority transformed by technology. Today's equipment includes advanced sensor systems designed to prevent accidents with precise anomaly detection.

A staggering 95% reduction in material-related incidents reports has been observed in companies embracing these standards. Yet, there remains one mystery in the mechanics of safety protocols...

Real-time analytics provide actionable insights, granting the ability to foresee maintenance needs before failures occur. But what's truly revolutionary are the cost savings achieved through such preventive measures; and that’s not the whole story...

Beyond protection against physical harm, these systems ensure data security and operational consistency. The next revelation could redefine industry standards.

Eco-friendly equipment is rapidly becoming the standard, with companies converting to electric forklifts and solar-powered logistics tools. The environmental impact is considerable and customers are taking note.

Reports reveal a 60% decrease in emissions from operations that switch, heralding significant environmental and cost benefits. The unseen element, though, involves regulatory effects...

Grants and tax incentives are constantly evolving to support eco-friendly initiatives, but seizing these opportunities requires inside knowledge. This deep dive could alter your strategic planning...

Material handling is no longer just about movement—it’s about sustainable growth. Get ready for the next twist that could shift your sustainability approach.

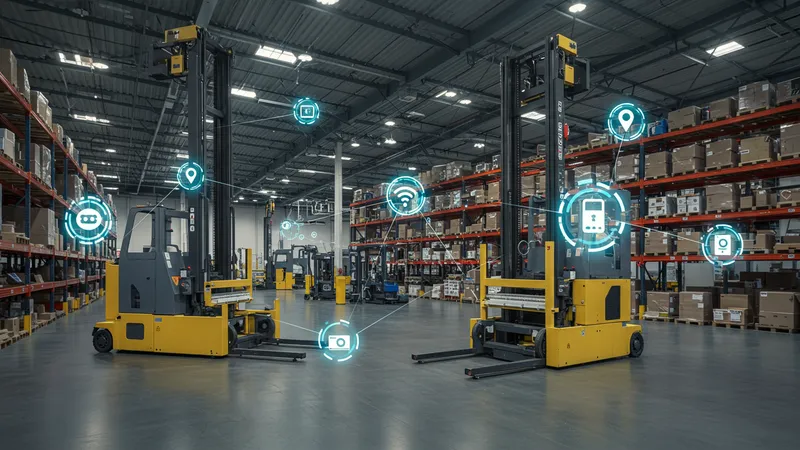

Internet of Things (IoT) systems are now seamlessly integrating with material handling equipment. This results in revolutionary data-driven operations that facilitate unprecedented oversight and control.

But the standout feature is device synchronization, which brings a 50% boost in operational visibility and efficiency. Yet, the breakthrough element is something few have anticipated...

Smart sensors provide real-time tracking and condition reports, optimizing maintenance schedules and workload distribution. Few realize the speculative opportunity lurking beneath this efficiency...

Operational insights gleaned from IoT integration allow for strategic foresight—predictable problem solving before issues arise. The upcoming revelation is bound to shift the paradigm of material logistics management.

Predictive maintenance, once considered a luxury, is now essential. By using sensors and analytics, companies can predict failures before they happen, preventing costly unscheduled downtime.

This approach is credited with cutting maintenance costs by up to 30%. But here's the secret advantage hidden within these predictive insights...

The real-time data analysis extends equipment lifespan by managing stress and optimizing usage patterns—an unexpected benefit that’s changing maintenance philosophies consequently.

These strategies are set to redefine the core framework of maintenance logistics. Stay tuned, as the following twist ties it all back together...

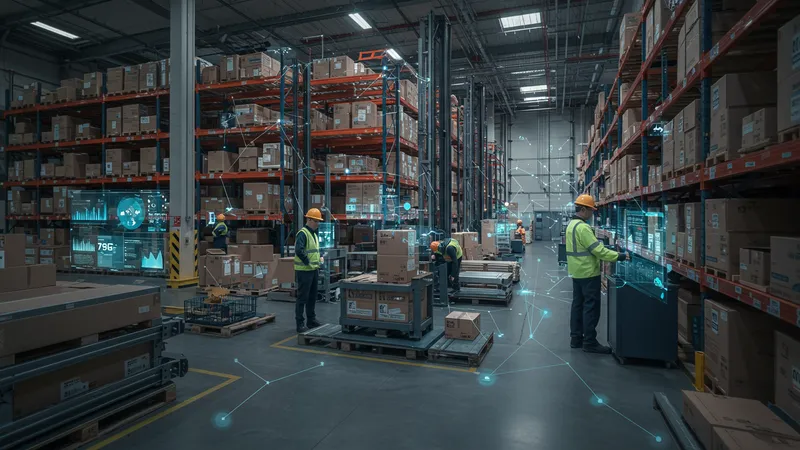

Data analytics have transcended conventional business operations, penetrating deep into material handling. Companies can now leverage big data to optimize routing, scheduling, and even staff performances with astonishing precision.

The staggering part is observing up to 20% reduction in time and cost inefficiencies. But this isn’t the most provocative element of data utilization...

Mining data for predictive modeling unlocks insights, forecasting demand spikes and equipment needs that ride shotgun to success. But one revelatory truth awaits in unexplored data terrains...

Transitioning to a data-centric operation model may be daunting, but the compounding benefits align perfectly with exponential growth opportunities. The next unexpected detail might just cause a complete strategic pivot.

Implementing new technology demands upskilling your team. Investing in comprehensive training programs ensures seamless integration of advanced equipment into existing workflows.

Astonishingly, training is often overlooked, despite its influence on achieving a 90% adoption rate for new technologies. But there’s a training dynamic often omitted in planning...

Bespoke training solutions tailored to equipment and operational specifics cultivate a proficient workforce adept at maximizing technological benefits, often doubling productivity gains. Yet there’s one more paradigm shift to consider...

Blended learning models—incorporating hands-on and digital methods—lead to rapidly accelerated learning curves and retention of new skills, ensuring continuous improvement. More lies ahead, as profound insights redefine organizational training philosophies.

Strategic investments in material handling focus on automation, sustainability, safety, and data integration. Understanding these pillars reveals the framework for constructing a future-proof logistical network.

Critically, each area not only elevates operational effectiveness but reduces long-term costs—a dual benefit increasingly recognized. The next unexplored angle adds an unexpected layer of advantage...

Interconnecting strategic investments magnifies their impact, compounding efficiency and innovation gains across operations. But that’s not the most astonishing outcome...

The synergy generated from this interconnected strategy gives rise to entirely new opportunities for market leadership. What happens next could forever alter your competitive edge.

AI applications extend beyond automation, offering scalability previously unimaginable. Intelligent systems optimize logistics dynamically, adapting to real-time demand and operational conditions.

The intriguing effect is on resource allocation, achieving up to a 40% improvement in operational capacity. However, the unexplored frontier promises a more innovative realization...

AI’s predictive capability not only forecasts but suggests optimized operational strategies. Organizations seizing this potential increasingly outperform their competitors. Yet the final unraveling of potentials could shift AI perspectives indefinitely...

Optimization strategies powered by AI aren’t merely reactive; they project growth paths, ensuring readiness for emerging market requirements and delivering scalable futures. Continuing on will uncover transformative insights reshaping operational scales...

Balancing cost and innovation is critical and challenging within the rapidly advancing sector of material handling. While upgrading seemingly demands significant investment, strategies exist to maintain fiscal prudence while pursuing advancement.

Intriguingly, organizations leveraging innovative cost recovery methods, like shared resources and partnerships, see reduced financial strain. Yet, an unexpected reconciliation offers substantial leverage...

Focusing on agile innovation—incremental enhancements ensures steady growth with minimized disruption. The synchronization of budget management with creative advancement is an artful balance.

The nimbleness to innovate without soaring expenses is a formula for enduring success. The next chapters open doors to strategies transforming conventional fiscal pressure into innovation-driven dynamism...

Implementing new systems and technologies can face resistance, often stemming from apprehension and tradition. Overcoming this resistance necessitates understanding and addressing root causes with tactful persuasion and openness.

Remarkably, involving stakeholders early and communicating a clear vision can shift resistance to collaboration. Yet, there remains a nuanced insight into this transformational journey...

Cultivating a culture of innovation dispels fears, fostering an environment welcoming of change. Credible advocates within the organization can serve as pivotal change agents, transforming models of resistance into progressive evolution.

These approaches lead to an ingrained cultural shift, embedding dynamism within organizational DNA. The next conceptual exploration fetches insights that further revolutionize material logistics dynamics.

Collaboration between tech companies, vendors, and clients is reshaping the landscape of material handling. This synergistic ecosystem boosts innovation and efficiency, resulting in seamless operations and mutual growth.

The compelling part reveals collaboration causing accelerated tech adoption and reduced time-to-market. This leaves one curious aspect, often overlooked in such partnerships...

Shared goals enhance resource alignment, facilitating co-developed innovations. This approach not only crystallizes partner relations but heightens operational agility, presenting a fresh perspective transformation.

The output of collaborative efforts establishes benchmarks, fostering a competitive edge through shared expertise. What follows after this exploration supports a provocative open field for future partnerships.

As industries push toward a future no longer tethered by outdated systems, embracing these transformative strategies becomes imperative. Those who harness the power of innovative material handling tools will define the next generation of market leaders. Now is the time to act—to explore, adapt, and propel forward.

Share this article with colleagues or bookmark it to revisit these vital insights. Let’s build the future of efficient operations together!